Keeping elevators reliable is part of maintaining a livable community. For HOA buildings, commercial elevator maintenance protects safety, limits downtime, and keeps costs predictable. This guide covers the rules, routine tasks, and key decisions boards need to make.

Commercial Elevator Maintenance: The Basics

In tall commercial establishments, having an elevator can be crucial to everyday building operations. To make sure those are running smoothly, proper and regular maintenance is a must.

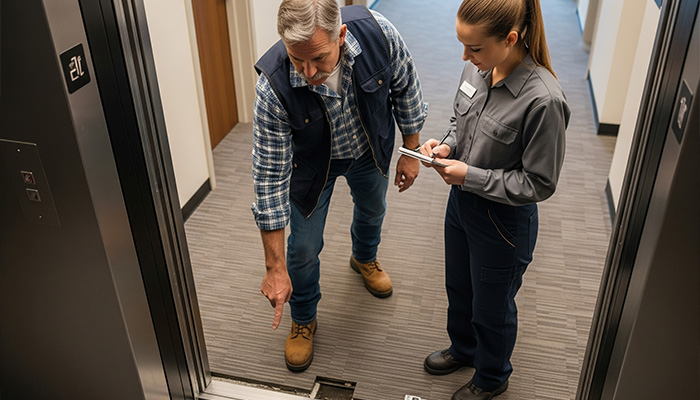

Commercial elevator maintenance is about more than service calls. It combines code compliance, daily checks, and planned work to keep equipment in good shape. When this work is clear and scheduled, the building runs better and residents feel it.

Most HOAs rely on a licensed elevator contractor for technical tasks. On-site staff can help with simple observations and documentation. A shared plan keeps everyone aligned and reduces surprises.

Codes and Standards for Elevators

Elevators operate under a tight set of rules. The core technical standard in the United States is ASME A17.1, also known as the Safety Code for Elevators and Escalators. Many jurisdictions adopt it together with CSA B44.

Fire and electrical rules also apply. NFPA 70 covers electrical work. NFPA 72 touches fire alarm interfaces and recall features that must work as designed.

Accessibility and building codes matter as well. ADA requirements guide call buttons, car dimensions, signals, and door timing. The International Building Code ties many pieces together, then each state or city adds its own rules. Your contractor should help track which edition is in force where your property is located.

Inspection and Testing Timelines

Most jurisdictions require annual inspections by the authority having jurisdiction. Inspectors review the machine room, hoistway, top-of-car controls, and key safety functions. They confirm that required tests have been completed and logged.

Safety tests run on set cycles. A common pattern is a yearly no-load safety test and a five-year full-load test. Fire service recall, emergency lighting, and communication features are checked on routine schedules, sometimes with the fire alarm vendor present.

Owners are responsible for the records. The inspector will ask to see current test reports, the maintenance control program binder, and any notices for open violations. Keeping these materials ready saves time and avoids repeat visits.

Elevator Maintenance Checklist for HOAs

Use this commercial lift maintenance checklist as a baseline and adapt it to your site and contract. Keep items short and easy to verify:

- Car ride quality, door opening and closing, and floor leveling.

- Door safety edges, light curtains, and photo eyes.

- Emergency phone or hands-free device and posted responder number.

- Alarm bell, lighting, fan, and car signage.

- Hall call buttons, lanterns, and position indicators.

- Machine room temperature, cleanliness, and clear access paths.

- Visible leaks or odors from hydraulic equipment or gearboxes.

- Governor seals, buffers, and overspeed devices are noted in service logs.

- Fire service Phase I and Phase II operations were tested per schedule.

- Logbook entries for every visit, test, and fault, plus close-out notes.

Your vendor should provide a site-specific list that meets local code. Please review the list with the board once a year and update it as the equipment changes. Tie the checklist to your regular commercial elevator maintenance visits so nothing is overlooked.

Contracts, Budgeting, and Vendor Management

Most HOAs choose one of two contract styles. A full maintenance contract bundles parts, labor, and routine tests for a set fee. An oil-and-grease contract costs less upfront but excludes many parts and repairs.

Ask for a clear scope. The contract should state response times, after-hours rates, included parts, excluded parts, and test responsibilities. It should be noted who is responsible for maintaining the maintenance control program binder and who meets the inspector. Align the scope with your building’s age, traffic, and risk tolerance, then budget across several years.

When Repairs are Needed

Even well-maintained systems will need commercial elevator repair at some point. Door operators, rollers, buttons, and relays see heavy use. Hoist ropes and hydraulic components wear over time.

Set simple thresholds for action. If a part fails frequently, consider discussing replacement rather than making repeat callouts. If downtime extends beyond the agreed-upon window, request a root cause report that includes a fix and a timeline, and then file it with your logs.

Safety, Access, and Resident Communication

Safety starts with access control. Machine rooms and pits must stay locked and clear of storage. Only trained personnel should enter these spaces.

Communication plan. A short notice about testing helps residents and avoids false alarms. Share the contractor’s hotline number and the management contact for urgent concerns. For high-rise sites, consider a standby plan for residents with mobility needs during planned outages.

Common Pitfalls to Avoid

Even well-planned programs can drift. Small gaps in daily habits or scope can snowball into shutdowns and surprise costs. Use this list as a quick gut check during vendor meetings, inspections, and budget reviews.

- Choosing based on price alone without checking the scope and parts coverage

- Letting daily observations slide and relying only on annual tests

- Skipping documentation and losing track of test dates

- Allowing stored items in the machine room or blocking access

- Ignoring door issues, which cause most shutdowns

- Extending upgrade decisions until repair costs spiral

Modernization: Knowing When to Plan an Upgrade

At some point, parts availability and repair frequency make upgrades sensible. Common targets include controllers, door operators, fixtures, and drives. These changes can improve reliability, ride quality, and energy use.

Good planning avoids extended outages. Ask your vendor for a condition report that ranks components by risk, cost, and lead time. You should develop a phased plan spanning multiple budget years to ensure fees remain predictable and aligned with your reserve study.

Modernization also presents an opportunity to enhance accessibility. Review car dimensions, signals, chimes, and button layouts against current ADA requirements. Better access serves residents and guests and supports resale values.

Roles and Responsibilities for the HOA

Boards set policy and approve contracts. Management coordinates contractors, schedules tests, and keeps logs current. On-site staff perform simple checks, post notices, and report issues.

Your elevator contractor maintains and repairs the equipment. They run tests, document results, and brief the board on upcoming needs. The inspector verifies compliance on behalf of the jurisdiction.

When each party knows its role, commercial elevator maintenance becomes routine rather than stressful. That stability is the real value of a well-run program.

Building a Simple Annual Plan

A one-page plan keeps your team organized and accountable:

- Map out inspection and testing months for each elevator

- Schedule quarterly review meetings with your vendor

- Refresh the elevator maintenance checklist at the start of each year

- Confirm emergency contact numbers and after-hours response terms

- Align modernization steps with the reserve study and project calendar

Revisit the plan after each inspection. Note lessons learned, parts that failed, and any code changes your vendor flags. Treat the plan as a living document that supports consistent commercial elevator maintenance throughout the year.

Training and Culture

Short reminders help staff spot issues early. Teach the team to listen for unusual noises, watch for leveling gaps, and note frequent door bumps. A quick call to the vendor at the first sign of trouble can prevent a shutdown.

Document any near misses that happen. If the car stalls and resets, write down the time and symptoms. Patterns often point to simple fixes that cut future downtime and reduce the need for urgent commercial elevator repair.

Timely Maintenance

Elevators are complex, but the path to reliability is clear. Set roles, follow the rules, use a practical checklist, and keep records in order. With steady commercial elevator maintenance, HOAs can protect safety and reduce surprise costs.

Maintenance Specialists Inc. offers a wide range of commercial property maintenance services. Call us now at 704.405.6000 or contact us online for more details!

Related Articles:

- Don’t Overlook Commercial Floor Drain Maintenance, Here’s Why

- Key Things To Know About Effective Parking Structure Maintenance

- How Can An Interactive Asset Map Help With Facility Maintenance?